This season is about exploration and evolution, and the mélange of strength with softness, embracing a wide spectrum across high impact activities through lifestyle, to outdoors and soft furnishings.

The fabrics possess much lighter properties while maintaining their core character and delivering impeccable performance.

An upward spike in outdoor sports, travel and fitness-related activities has directly impacted a surge in the demand for performance and technical fabric blends with designers and brands maintaining a key focus on those areas. Function and utility also follow close behind with the rise of reengineered options.

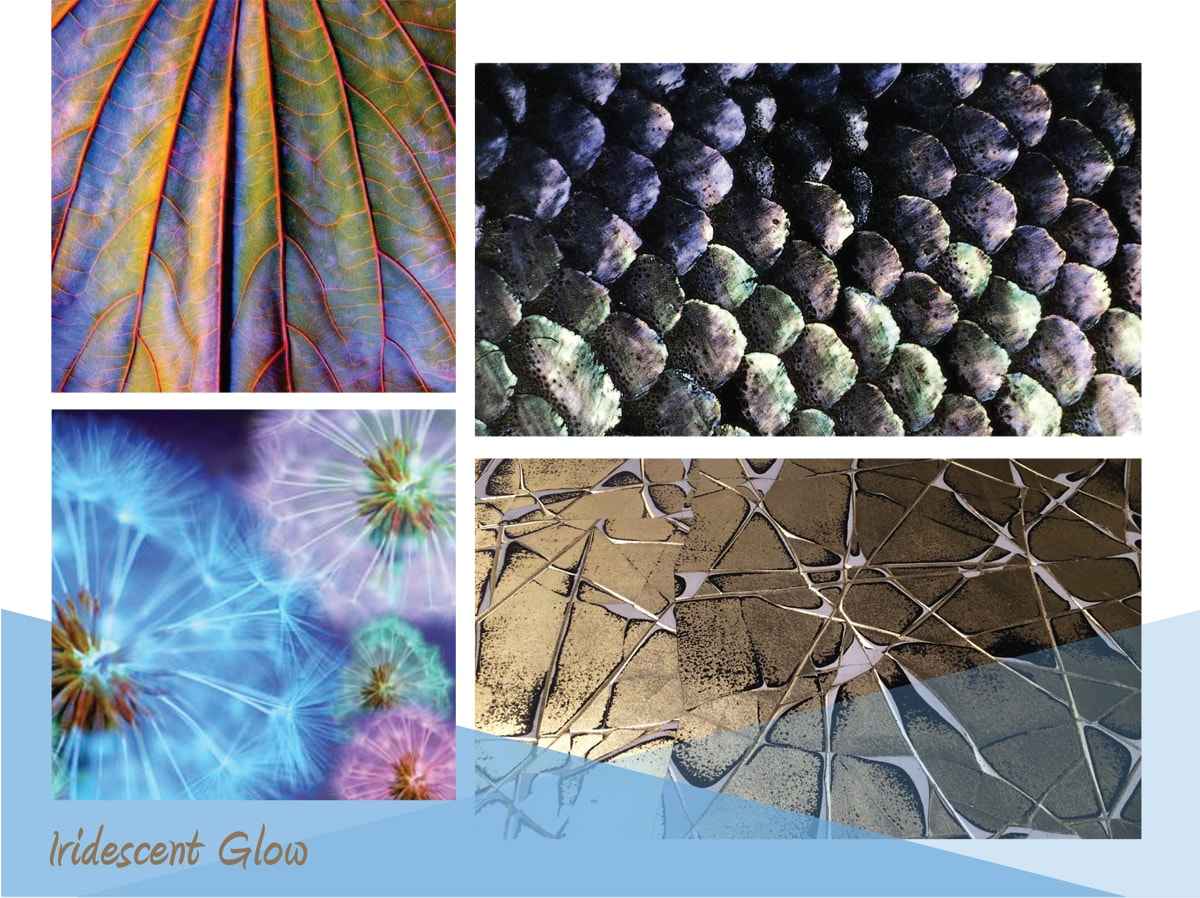

A softer and more glamourised approach is obtained with the incorporation of lustrous yarns that serve the demand for opulence and metallic sheen. The products are more sensual and tactile, featuring a soft and silky touch with iridescent finishes.

After analysing the themes presented at various trade shows, reports such as the ones released by SpinExpo and ISPO Textrends, and validating the findings with top Indian players – Vidhya Shankar from Ganapathi Chettiar; Vikas Wadiker from Reliance Industries; Roopali Beri from Vardhman; and Luv Jain from RSWM, Apparel Resources and FFT teams present to you the top directions in yarns for the approaching season.

Key trends in yarns and its end-products have been highlighted, by defining individualistic properties and colour ways that provide a fair idea about the future of textiles for the upcoming Spring/Summer 2019 season…

Since the past few seasons, high tenacity yarns have had a growing effect on the market owing to their toughness and rigidity, but this season, the trend is shifting towards fabrics that are softer and that possess enhanced flexibility.

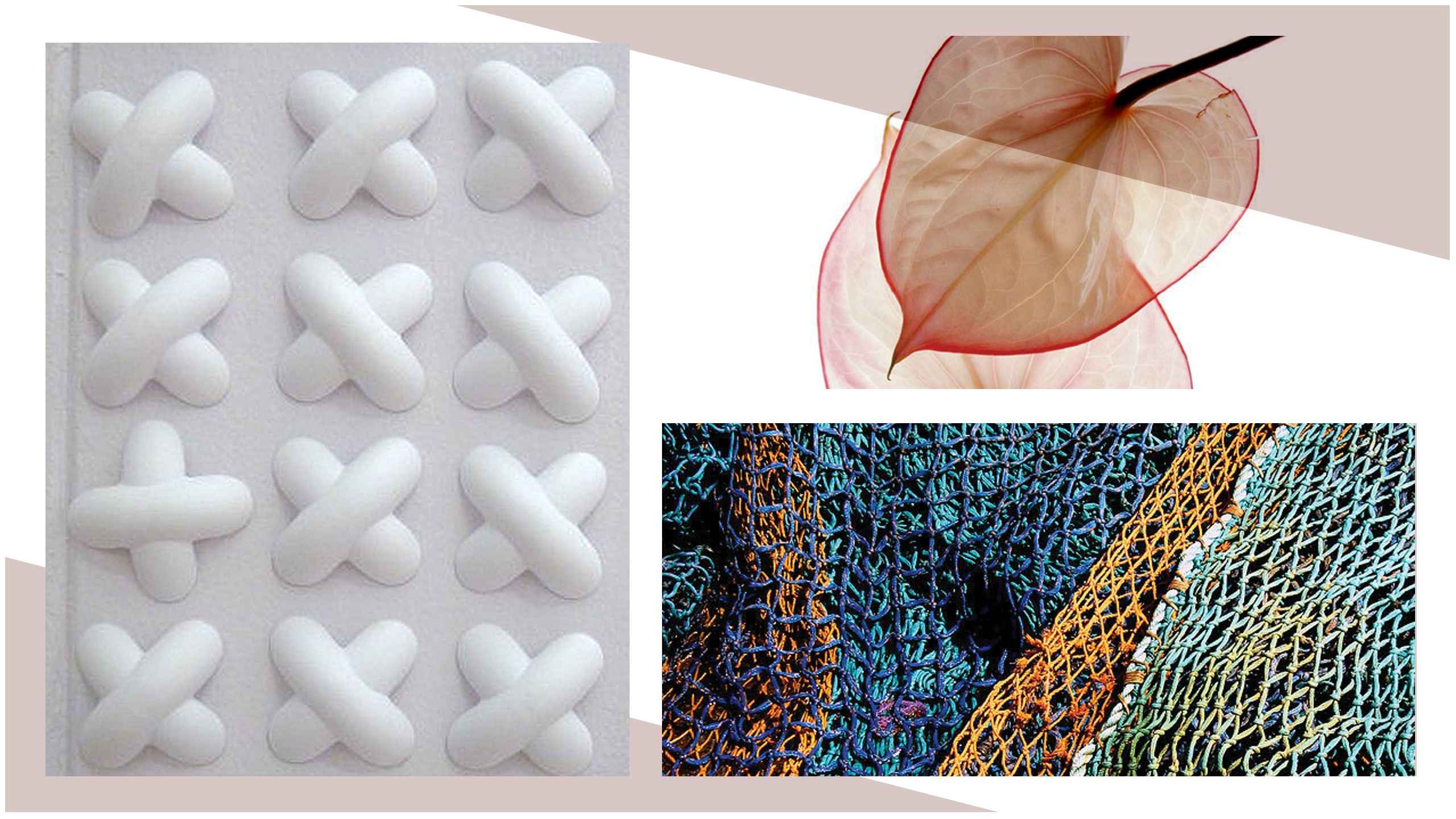

The trend explores properties of strength and tenacity, where only the toughest, resilient and most durable fibres come into play. Key directions include anti-tear and anti-stress materials, innovative body mapped versions of reinforced engineered zones, high compression fabrics that embrace the wearer anatomically, and engineered fabrics that lock on impact.

Grit and Glamour

FIBRES, YARNS & FINISHES

Aramid yarns

High tenacity yarns

Graphite-inspired strength – 200 times finer than human hair

Natural, manmade and synthetics fibres feature as blending partners

Classics, including gabardine and twill, are updated in lighter weight with high tenacity yarns

Tough membranes and coatings for shell-like protection

Stretch laminates for added protection to embedded high tenacity yarns

Breathable DWR finishes

High power spandex/elastane for high compression

Multi-functional yarns and finishes for added performance

Yarn and finishes boasting of cooling technologies

TARGET MARKETS

High impact sports

Road cycling/mountain biking

Rock climbing

Lifestyle – athleisure/street sports

Skateboarding

Travel

Outdoor equipment – tents, backpacks, sleeping bags

A new level of lustre is achieved by incorporating renewed luminosity and brightness, without abandoning the luxury of touch and feel. Rich and opulent textures take centre-stage through the brilliance of yarns to achieve optical and tactual stimulation.

Compact fabrics with glossy substrates contest against more textured constructions and optical prints while lacquered looks emerge as a key trend.

The focus is on functionality wherein cool touch, UV protection, high compression, moisture management and thermal regulating ingredients come into play. The colour palette comprises of bold, striking hues to attain a vintage classic undertone mixed with metallic overtones. Techniques such as laser cutting and openwork mesh in illuminated yarns are tapped to add a decorative element to the products.

Iridescent Glow

FIBRES, YARNS & FINISHES

Reflective yarns, prints and trims

Rainbow reflectivity in finishes via coatings and prints

Iridescent yarns

Super chlorine resistant spandex/elastane

Tri-lobal yarns for new generation shine

Metallic coatings, transfers and prints

Traditional foil prints

Dazzling bright tone through lamination and intense yarn dyed synthetics

Watermark yarn relief and coatings for iridescent appeal

Gleaming trims in gold and titanium

Glow in the dark yarns and finishes

Fluorescent and phosphorescent yarns and finishes

TARGET MARKETS

Glamourised athleisure segments

Lifestyle/urban

Stylish workout wear with high levels of performance

Beach sports apparel and swimwear

Hiking

Aerobic wear – dry or aqua

Soft equipment

Into the Spectrum

High compression fabrics feature a four-way stretch property that takes on a biomimetic approach to the muscular structure of the body. Reflective fabrics and trims emerge in feather lightweights alongside high-tenacity fabrics that make use of micro fine steel-strength aramid fibres.

The trend focuses on performance boosting characteristics that imbibe a robot-inspired appearance in terms of the structure of the product. Precise, compact and protective, the materials are softer and more comfortable wearability-wise than their previous versions.

Intelligent interfaces on the technical or face of the fabric improve performance by offering cooling effects, water repellence, UV protection, moisture management and quick dry technology.

FIBRES, YARNS & FINISHES

Man-made fibres – lyocell, modal

Silver, zinc and copper yarns and finishes

Coloured coatings

FIR and NIR yarns, Natural touch synthetic performance yarns

Spandex/elastane for stretch, recovery and comfort fit

Micro-encapsulated yarns and finishes – mineral embedded yarns

Air textured yarn technology

Textured synthetic yarns for a grainy, natural touch

DWR membranes

High-performance polyester and nylon feature

Nano membranes

TARGET MARKETS

Travel

Active intimate apparel and socks

Beach sport

Yoga, Pilates

Golf, tennis

Running

Outdoors

Soft equipment – backpacks

Hybrid Territory

Sustainability sits at the core of the fashion and textile industry placing an emphasis on the juxtaposition of a new generation of synthetics, natural and man-made fibres and how they can come together to achieve a new level of expertise.

An upturn in higher performance recycled nylon and recycled polyester with bio synthetics is observed in terms of synthetics, with a strong inclusion of natural fibres from BCI cotton, pima cotton, merino wool and the luxury application of silk. Lyocell and micro modal feature as man-made options.

A combination of a selection of these blends would serve as a hybrid approach to create new sustainable options within the sector. The products feature a strong natural characteristic that is observed through touch and visual feel, updated with performance.

FIBRES, YARNS & FINISHES

Cotton and cellulosic for super soft natural touch

Hemp and linen in refined yarns for a grainy aspect

Reduced water and energy consumption for a sustainable aspect in finishing and dyeing

The inherent function of merino wool in terms of thermal regulation and comfort for the Spring/Summer season

Micro modal, lyocell and silk for added softness

Moisture management and anti-bacterial as key performance factors

Recycled nylon and polyester

Bio-based spandex/elastane and eco-friendly spandex/elastane

Built-in performance yarns – moisture management, UV protection, anti-bacterial, cooling properties

Bio-synthetic insulation for summer delivery in hybrid blends with recycled polyester

Neoprene-free recycled fabrics for water sports

Texturised synthetic yarns with a cotton touch and built in performance

TARGET MARKETS

Athleisure l Lifestyle l Yoga

Travel l Urban cycling l Outdoors

Water sports – surfing, kite surfing, kayaking, and windsurfing

Soft sports l Golf/Tennis/Hiking

Soft equipment – tents, sleeping bags, backpacks, shoes

Back to the Future

The trend observes a weightless direction across micro-fine hosiery-inspired knits to micro-light trims and accessories, through engineered structures and technicalities.

The structure of the yarns enables these materials to know when and how to react and protect, guaranteeing enhanced performance and a truly visionary approach in the sportswear sector. Artificial intelligence and automation inspire fabric construction, boosting and strengthening the motion and friction between the body and the garment.

Cool touch, compression, UV protection and anti-bacterial pose as key properties delivering barely there, ultra-lightweight fabrics that provided unmatched performance. A strong influence in engineered fabrics through body mapping specific functions into key zones in fabric constriction leads to a more seamless result.

FIBRES, YARNS & FINISHES

High powered spandex/elastane

Embedded sensors linked to apps to monitor performance

Power stretch spandex/elastane – super chlorine resistant

Iridescent yarns

Metalloplastic yarns

Futuristically optical heat transfers

Thermochromatic yarns and transfer prints

Reflective technology in yarns, prints and finishes

Day-Glo trims and yarns

Phosphorescent micro-fine yarns

PU tapes – heat bonded seams

FIR and NIR yarns for enhanced performance and comfort

Moire effects

Variable modulus fabrics

Patina surfaces through yarn content or finish

TARGET MARKETS

Track cycling l Running

Marathon & Triathlon l Athletics

Fitness & Gym apparel and soft equipment

Active intimate apparel and bodywear

Cross training and cardio classes

Wearable technology

Post a Comment