Threads are the most significant trims in the sewing process but that’s not the only use of thread in today’s time. Over decades, the thread industry has transformed multifold in terms of innovations and the applications where it is being used, both in apparel and non-apparel industries. Besides, there are players who have been successfully replicating concepts like on-demand (which predominantly started with apparel manufacturing) in thread industry as well, considering the fact that production units are generating a huge amount of wastage of not just fabric but also trims like thread which need to be controlled for better sustainability of business.

On-demand thread colo u ration technology by Coloreel

On-demand concept is gaining ground in the apparel industry and pushing technology suppliers to develop technologies for every possible area of the supply chain where a large number of inventories are irrationally being used. Till date, the on-demand concept is majorly being used on the sewing floor which is supported by allied pre-production processes such as designing, pattern making and fabric cutting. However, the principles of embroidery have not changed since a very long time. Today’s embroidery machinery still presents various limitations in terms of efficiency of the embroidery processes , significant set-up and downtime, colour range limitations, waste of raw material and limited resource efficiency. Not just big embroidery workshops, even the small embroidery shops are also stocked with a huge number of coloured threads which are generally wasted, if not used. Sweden-based Coloreel is transforming the way embroidery industry has been working since decades with its breakthrough on-demand technology that enables instant thread colouring during production.

Mattias Nordin, CEO, Coloreel told Apparel Resources , “Our first product based on this technology is a thread colouring unit designed to be used with industrial embroidery machine. Soon, we will be launching the same technology for knitting, sewing and weaving too.” He further explained that requiring only one reel of thread, the unit will allow freedom to create unique embroidery without limitations in colour use. “Also, it improves efficiency by minimising re-threading time and significantly reducing the need for keeping stock of thread,” claimed Mattias.

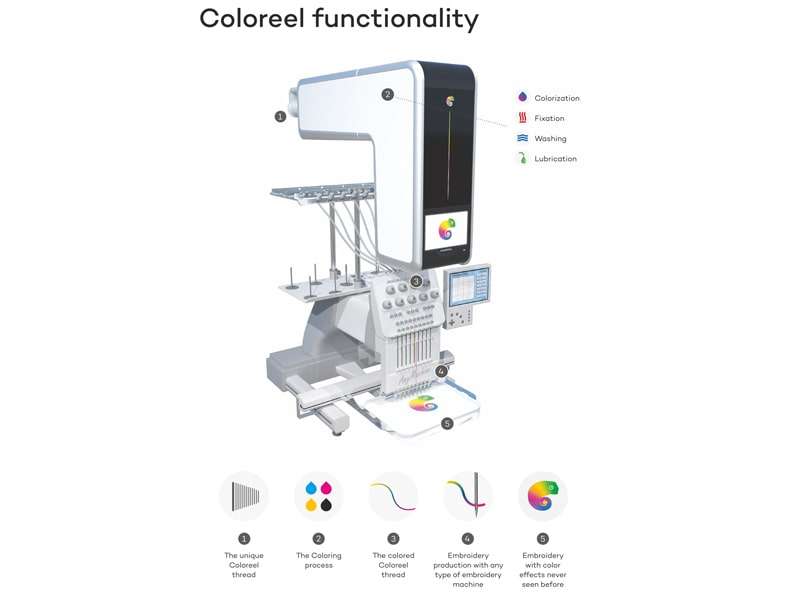

Functionality of Coloreel

Coloreel’s thread colouration technology is a reversed L-shape machine, the Coloreel Unit, which weighs around 53 kg. It is hanged above the embroidery machine and the only thing that connects them is the stitch sensor to keep a track of where the user is in the embroidery process. Threads can be fed from an input slot positioned at the top of the unit. Once the thread goes inside, the straight tunnel-shaped part performs the following tasks: colourisation of thread according to the requirement, fixation, washing and lubrication. This process is done with the support of ink cartridges, washing fluid, lubricators and carbon filters mounted inside the machine. The processed thread then comes outside from the tunnel which is adjoining the upper part of the machine in 90 degree angle. The thread then goes directly into the embroidery machine and the usual operation of embroidery takes place on fabric or garment.

Now the most important question that arises is how the thread gets through the colouration process. Mattias explained, “Coloreel Studio, developed by us, is the software for colourising embroidery design.” The program is the link between digitisation software and the Coloreel Unit. The manufacturers can use the same DST-file that controls their embroidery machines.

The digitisation process in Coloreel Studio starts with the addition of all the colours and effects that the users need for their design. The understanding of the program does not need any prior embroidery background for the operator. According to Coloreel, the following three tips can ease the digitisation of thread colouring process:

H ow Coloreel is making a difference

The biggest benefit out of this technology is that the thread inventory and stock can be reduced to a minimum. There is no longer a need to hold a large thread stock with different colours. “The companies performing embroidery using Coloreel technology only need one white thread that the Coloreel unit dyes into the colour of their choice,” stated Mattias, adding, “Improvements include logistics, flexibility, reduced scrap, and reduced working capital.” Importantly, the users need to buy white thread from Coloreel only since that thread is tested and verified for use by the company in the Coloreel unit. “One can’t use any other thread of different brands,” cleared Mattias.

The most significant benefit of Coloreel unit is that the user can get unlimited range of colours and new design possibilities which is not possible through the traditional method. Besides, embroidery quality is impeccable as keeping track of thread tensions for the embroiderers has been reduced to only one needle instead of 9, 12, 15 or more. Changing the colour of the thread and not needle also brings in a smooth backside without tie-outs and trims. “It will look exactly as a one-colour design. The time-consuming task of changing thread reels between orders is long gone,” maintained Mattias. Another aspect relates to sustainability. In Coloreel unit, dyeing is required only on the amount of thread required instead of the whole thread cone which reduces material waste and minimises the use of resources. “By bringing these solutions, Coloreel is revolutionising the embroidery industry for the better and is the next significant milestone for your business,” concluded Mattias.

Smart conductive threads by AMANN Group

An industrial thread leader, AMANN Group has made it possible to integrate ‘conductive technology’ through smart threads in daily life products such as car seats, home textiles and even in clothing. The continuous innovation of the Germany-based thread supplier has made it possible to replace plastic switches, sensors and conventional antennas. The intelligent threads from AMANN called ‘smart yarns’ no longer only fulfil the classic role as sewing and embroidery threads but are also taking up the function of performing as conductors of electricity or data in all sorts of applications.

In the first-of-its-kind innovation, AMANN has developed conductive threads which can be used in embroidered touch switches. These switches can, in future, take over the function of today’s plastic switches and buttons. The textile switch, which is embroidered onto the lampshade, is made from the silver-coated special sewing and embroidery thread and can readily replace toggle switches and dimmers. A single touch with the finger is all it takes to operate it. The textile switches not only represent a special design element, but they are also easy to manufacture and more pleasant to touch.

“These threads can sense the finger movement and work as conductive material in order to light up the lamps or bulbs at home, making a significant contribution to the sustainability of components and products, especially when it comes to avoiding the use of materials that are difficult to recycle, such as plastic and other synthetics,” elaborated Barbara Binder, Head of Global Marketing, AMANN Group .

Not just embroidered touch switch, AMAAN has integrated these threads in different other applications as well. One of these applications uses AMANN’s thread in RFID label that counts washing cycles. Workwear in the medical industry has to fulfil particularly tough requirements. Depending on the situation and stress, it is recommended or required to change clothing every other day. This, of course, means a high wash frequency with disinfecting cleaning methods and agents, which can prove to be a tough test for clothing, as the textile fabric should last as long as possible. RFID technology – or more precisely, transponders made of fabric that are sewn into the workwear and transmit the relevant data to a piece of software – offers a reliable means of control. At the heart of the washable and robust ‘radio label’ is the smart steel-tech thread from AMANN. This can be worked into a material, for example, in order to produce the antenna-equipped labels.

Furthermore, AMANN has innovated the way car seats have been operating over the years. It has come up with textile switch for car seats which is made up of highly conductive silver thread and enables adjustment of the backrest. Whenever a person presses this switch, car seat moves forward or backward sensing the touch of fingers.

“We have developed steel-tech threads for embroidery and stitching which contain metal. But, when one touches this thread, he/she feels it is quite soft, flexible and might not get a hint of metal inside it,” informed Barbara.

Post a Comment